Back to Learning Resources

Planning for Quality - System

You need to plan for the requirements of the quality management system (in addition to planning for delivery of your product or service)

Tags:

In addition to planning the delivery of your product or service, you will also need to plan for the requirements of the quality management system itself.

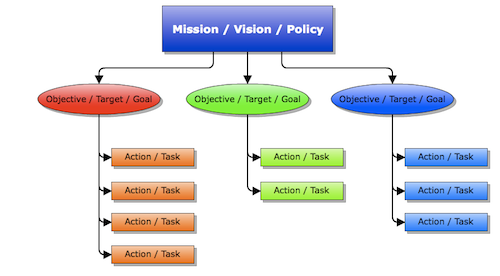

This kind of planning for quality is very much like developing a business plan and does not need to be a separate process. It begins with setting the overarching “mission statement” which, in the context of ISO 9001, is the quality policy. Typically these are high level statements like “We commit to meeting our customer expectations”, “We will strive to be the leading provider of XYZ widgets in Australia”, etc. and are usually over a longer time frame of the order of 5-10 years.

There are many business analysis techniques to help this future gazing.

The quality plan translates the aspirational mission statements into an action plan (pictured right).

Setting Objectives

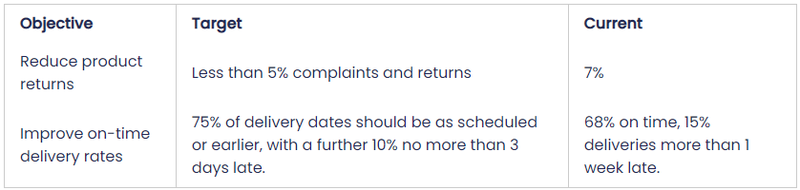

The next level down is setting objectives that are consistent with the goals stated in the policy, but over a shorter time frame – usually 1-2 years. You want to know when these objectives have been achieved, so they need to be concrete, measurable goals. You also want to have a fair chance of success, so make sure the goals are for things that you have control over and are realistic. Quality objectives will also address areas of concern that have arisen out of business analysis and review processes.

For example, let’s say the quality policy states (as many do):

“We commit to meeting our customer expectations”.

Here are some objectives consistent with this policy, along with metrics and targets:

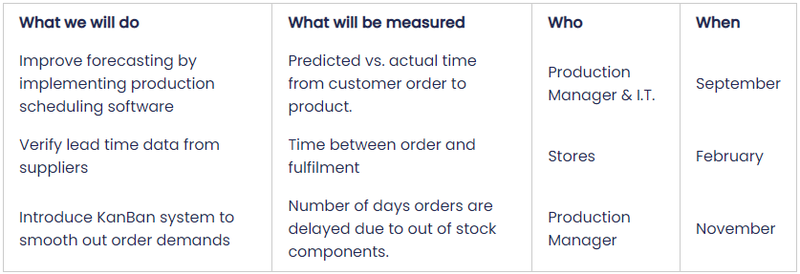

Action Plan

Once you’ve decided what the objectives are, you’ll need to formulate a strategy or action plan for achieving them. What exactly you will do, what will be measured, what constitutes success, who is responsible and what will be needed to make it happen. (Pretty much the same as for a project quality plan: requirements, acceptance criteria, methods and resources.)

This will require a good understanding of the current situation, problems that need to be addressed, and opportunities for improvement. Top management will need to be involved to allocate & approve appropriate resources.

For measurements, try to use metrics that normalise the measurement against other factors to keep it in context. e.g., if sales double, the raw number of customer complaints may go up – a seeming failure, but if the metric of complaints per unit sales decreases then the true story is success.

Here are some example actions to be taken in order to achieve the objective to “Improve on-time delivery rates”

Review and Revise

Finally, do what you planned to do and review the objectives to see if it worked. Then update the plan.