Back to Learning Resources

Competence and Awareness

Personnel should be competent - what does this actually mean ?

Tags:

In essence, the standard states that ‘person(s) doing work… shall be competent’. Most businesses take care of this, although record keeping often needs improvement to satisfy standards requirements.

The ISO 9001 quality management standard also requires your people to be ‘aware of the quality policy… objectives… and their contribution to the quality management system’. Similar requirements for Awareness also exist in the ISO 45001 safety and ISO 14001 environmental management standards. This requirement is more often neglected.

Competence

It really is not difficult. Just work out what you need, see what you have, and then fill in the gaps. Check to see it is working, and keep records to show you do it.

There is no requirement to document how you manage competence and awareness.

You just have to do it and keep records to show that you do.

The standard requires competence in work affecting “the performance and effectiveness of the quality management system”. This means that when you are determining needs, providing training, and keeping records, you need to include the requirements of the quality management system as well as requirements for the product or services you provide.

Step 1: Work out what you need

It’s very common to think about this when you write a job advertisement. You can use this mindset when writing job descriptions and determining competency requirements. Start with the responsibilities of the role and then think about what skills are needed to fulfil them. You may want to add in requirements that wouldn’t normally be included in a job advertisement, like knowledge specific to your organisation that will will be provided in on-the-job training or induction, e.g., “Awareness of our Quality Management System”.

If you’re starting from scratch, one approach is to ask everyone to describe their own duties, and what skills are needed – just make sure you tell them why, so they know you’re not trying to replace them! You can then pass those descriptions up and down a level on the organisation chart to get a different perspective on the expectations for that role.

Knowing what you are expected to do makes it easier to know when you are doing a good job, and that increases employee satisfaction.

Step 2: See what you have

Education, training, certificates, licenses, experience, skills, awareness,… you’ll want to have records for these.

This is obvious when you are bringing in a new hire and filling out a new personnel file, but you’ll need to have a way to track this for your existing employees whose knowledge increases over time with experience and training.

It is common to add these kind of records to a personnel file, but this doesn’t allow you to get an overview of the assets and gaps, and tracking expiry dates is nigh impossible. Adding these competencies to a list, spreadsheet or database will make life easier.

Don’t get carried away collecting records for everything. Stick to what is relevant to your organisation.

Step 3: Fill in the Gaps

Gap Analysis is where you compare the ‘needs’ to the ‘haves’, and find the holes.

This is pretty straightforward when there’s not too many employees and not too many competencies, but it can get quite tricky as the numbers increase.

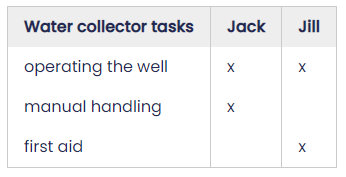

You can use a database (e.g., Toolbox), spreadsheets, or a simple table:

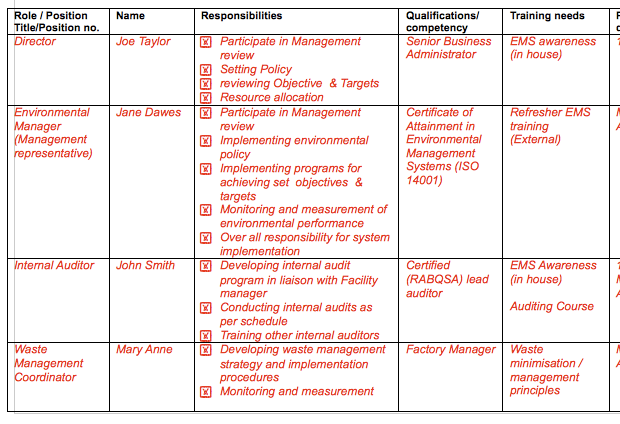

Here’s an example of a table ‘Responsibility Matrix, Training Needs Analysis’ included in the Environmental Management System Tool from the Australian Department of Sustainability, Environment, Water, Population and Communities

Once you’ve identified the holes, make a plan for filling them. This doesn’t have to be lots of dollars spent on formal external training. Other methods are perfectly acceptable: internal training, classroom, on-the-job instruction, ad-hoc/informal, mentoring, … Whatever works for you. Just keep records, which is easy for formal training, but a bit harder to remember to do for informal methods.

Check to see it worked

Training does not necessarily equal learning.

You will need to assess whether the training you provided, internal or external, has been effective in closing the gap you identified. In some cases this assessment will be provided in the form of a licence or certificate from the external training body.

For internal training you can use other methods:

- Direct supervision of work by a competent operator,

- Extra inspection of the employee’s work,

- A written test after the training,

- A practical test after the training,

- a combination of the above.

Particularly for external training, it’s a good idea for managers and employees to go over what was learned and how the material contributes to the employee work.

Awareness

This seems to be a ‘fuzzy’ one, but it’s not really. The ISO 9001 clause on Awareness talks about making sure people know how their activities fit into the business – its strategy, products & services, and the quality management system. This content would usually be part of the initial job orientation/induction.

For activities that don’t directly affect the product or service, it may not be obvious to staff how their activities affect the customer and quality, or impact on safety or environmental aspects. Having an overview of your processes (e.g. a process map) and top level process documentation can help define where the activities fit.

Awareness of the quality/safety/environmental management system is usually is taken care of by in-house training that should include:

- the quality / safety / environmental policy,

- significant quality / safety / environmental aspects of their activities and related work instructions,

- objectives and targets,

- their role and responsibilities in the quality / safety / environmental management system,

- safety / environmental emergency action plan,

- where & how to access information,

- how to report incidents,

- how changes can be requested (e.g. a document change request)

- how updates are posted,

Changes occur and people forget, so don’t restrict awareness training to induction.

Records for Competence and Awareness

You’ll likely need the following records:

- written job descriptions and their competency requirements,

- paper or electronic copies of licences, certificates, training records, etc,

- meeting notes with attendees listed (e.g., for a safety briefings),

- the gap analysis (table / list / matrix),

- training dates (a plan, a calendar), and

- training records once training has been completed.

Rinse and Repeat

Roles and responsibilities change over time and employees develop new skills, so you will need to repeat the analysis periodically. Conducting regular Performance Reviews is one method.

Also, new needs can arise if the business decides it wants to offer new services, has changed the way things are done (e.g., changes to a process, new software systems), or there have been changes to regulatory or customer requirements. If not otherwise, these changes are likely to come up as part of Management Review.